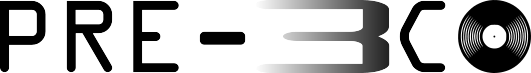

PRE-ECO is for an exploratory study into a new approach to the problem of design, manufacturing and analysis of printed composite materials.

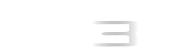

Additive manufacturing brought to the emergence of a new class of fibre-reinforced materials; namely, the Variable Angle Tow (VAT) composites. AFP and FDM machines allow the fibres to be relaxed along curvilinear paths within the lamina. In theory, the designer can conceive VAT structures with unexplored capabilities and tailor materials with optimized stiffness-to-weight ratios. In practise, steering brittle fibres, generally made of glass or carbon, is not trivial. Printing must be performed at the right combination of temperature, velocity, curvature radii and pressure to preserve the integrity of fibres. The lack of information on how the effect of these parameters propagates through the scales, from fibres to the final structure, represents the missing piece in the puzzle of VAT composites, which today are either costly or difficult to design because affected by unpredictable failure mechanisms and unwanted defects (gaps, overlaps, and fibre kinking).

Objectives

Multi-scale mechanics

Implement global/local models for the simulation and analysis of printed composites with unprecedented accuracy from fibre-matrix to component scales.

Defect quantification and propagation

Develop a (hybrid) metamodeling platform based on machine learning for defect sensitivity and optimization.

Design for manufacturing

Bridge the manufacturing signature with the final structure in a multi-scale sense for setting new rules and best-practices to design for manufacturing.

People

-

Alfonso Pagani is the coordinator of PRE-ECO project and serves as associate professor at the Department of Mechanical and Aerospace Engineering, Politecnico di Torino. He earned a Ph.D. in Aerospace Engineering at City University of London in 2016 and, earlier, a Ph.D. in Fluid-dynamics at Politecnico di Torino under the supervision of Prof. E. Carrera.

In 2018, Alfonso joined California Institute of Technology as visiting associate to work on acoustics of meta-materials. Also, he spent research periods at Purdue University in 2016, where he worked on micro-mechanics of fibre-reinforced composites with Prof. W. Yu; RMIT Melbourne in 2014, where he developed models for flutter analysis and gust response of composite lifting surfaces with Prof. E. Carrera and M. Petrolo; at Universidade do Porto in 2013, where he carried out investigations on the use of RBFs for the solution of equations of motion of higher-order beam models with Prof. A.J.M. Ferreira; at London City University in 2012, where he formulated exact, DSM-based models for metallic and composite structures with Prof. R. Banerjee.

Alfonso is the co-author of some 150 publications, including 90+ articles in International Journals, which have collected more than 1200 citations (h-index 21, source: Scopus). He acts as a reviewer for more than 20 International journals and is associate editor for Advances in Aircraft and Spacecraft Structures, an Int’l Journal (Techno-Press) and the International Journal of Dynamics and Control (Springer).

-

Matteo Filippi is Assistant Professor at the Department of Mechanical and Aerospace Engineering. He earned a BSc in Aerospace Engineering at Politecnico di Torino in March 2009. Afterwards he attended a MSc in the same university in December 2011, presenting a thesis on higher order one-dimensional structural models applied to static and dynamic of stiffened thin-walled structures, and a PhD in Fluid-dynamics in 2015, defending a work on aeroelasticity of rotor blades.

His current research interests include, but are not limited to, rotor-dynamics of helicopter blades and turbines, nonlinear analysis of composite structures, wave propagation and noise, as well as metamaterials. He is the co-author of more than 70 Journal articles on those topics.

-

Salvatore Saputo is a mechanical engineer currently working as an assistant professor at Politecnico di Torino. His main research activities involve the mechanical behaviour of composite aeronautical structures under low/high velocity impact, and the numerical and experimental investigation regarding the thermo-mechanical properties of Ni–Ti shape memory alloy used to realize powerful miniaturized actuators. He got his BSc with an activity concerning the effects that the shape relationships of a bottom-heated canal have on a controlled airflow in mixed convention. Then, he gained his MSc in December 2010 at Seconda Università Degli Studi di Napoli discussing a thesis about the optimization of skins and core of a trunk in unidirectional composite fibre material with a sandwich structure. Posteriorly, in April 2016 he obtained his Ph.D. at the University of Campania Luigi Vanvitelli with a thesis concerning the development of numerical procedures for intralaminar damage evaluation in composite material induced by low-velocity impacts.

-

Riccardo Augello is a researcher at Politecnico di Torino. He obtained his Bachelor's degree in Mechanical Engineering from Politecnico di Torino in 2014 by discussing a thesis on the evaluation of the dissipated power of Gaussian specimen in very-high-cycle fatigue tests. Afterward, he earned a Master of Science degree in Mechanical Engineering from Politecnico di Torino in 2016. His master thesis topic was “Multibody simulation of landing mission phases for robotic exploration”, which was undertaken after an Internship period at Thales Alenia Space.

Riccardo Augello started working at Politecnico di Torino in January 2017 under the supervision of Prof. Erasmo Carrera, and he started his Ph.D. program in Mechanics in November 2017. His doctoral project was about micropolar theories and was carried out in collaboration with the City University of Hong Kong, where he spent six months in 2019.

In the framework of PRE-ECO, Riccardo is developing advanced theories based on nonlocal mechanics, including the geometrical nonlinear analysis for the large deflection and post-buckling of composite structures.

-

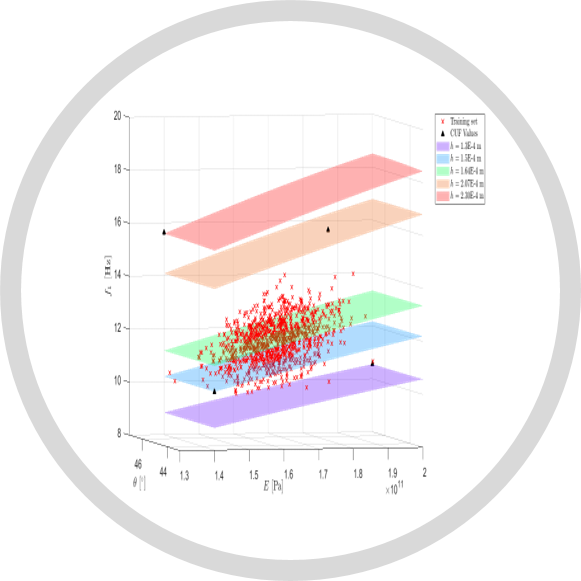

Alberto Racionero is a PhD student at Department of Mechanical and Aerospace Engineering, Politecnico di Torino. He graduated in September 2019 as an Aeronautic Engineer at ETSIAE (School of Aeronautics of Polytechnic University of Madrid). He developed his Master’s thesis at MUL2 group, as a part of the Erasmus student exchange, working on the surrogate modelling of CUF via Artificial Intelligence. Priorly, he obtained his Aerospace Engineer bachelor degree at ETSIAE by discussing his bachelor project developed at ITP Aero, where he worked with in-house CFD solvers. His current research topics are related with defect modelling, sensitivity analysis, surrogate modelling and optimisation of composite structures.

-

Jiahui Shen is a Ph.D. student at the Department of Mechanical and Aerospace Engineering, Politecnico di Torino. In September 2019, he came to Lisbon and joined CERIS as a short-term visiting student. At Lisbon, he developed the finite element simulations via ABAQUS under the supervision of Prof. João Ramôa Correia and Eng. Mário Rui Arruda. In June 2020, he obtained a Master Degree in Civil Engineering at Southeast University, China. Priorly, his research area focused on applications of new composite materials to Civil Engineering and analysis of structures under extreme environments, such as real fire conditions. At present, he is doing nonlinear analysis of concrete structures based on the CUF framework and damage detections in concrete structures via artificial neural networks under the supervision of Prof. Alfonso Pagani.

-

Rebecca gained her MSc in Aerospace Engineering focused on Space applications in April 2022. The topic of her master thesis was “Multiscale models for the hygro-thermo-elastic analysis of heterogeneous composite materials and structures”. Her areas of research concern micromechanics analysis of composite and the study of VAT material focused on thermal aspects. She is involved in a project developed within the MUL2 research group with the University of British Columbia and the University of Washington concerning the study of process-induced deformations and residual stresses in composite materials.

-

Piero Chiaia is a PhD student at the Polytechnic University of Turin. In October 2022, he got with honours the Master's Degree in Mechanical Engineering at Polytechnic University of Bari, discussing a thesis on Fluid-structure Interaction and Multi-field problems entitled "Advanced finite elements for the large displacement (and large strains) analysis of materials and structures". In November 2022, he started a PhD program in Mechanical Engineering at the Polytechnic University of Turin in collaboration with the MUL2 research group under the supervision of prof. Alfonso Pagani under the PRE-ECO project. His research project is focused on refined finite element models based on CUF for hyperelasticity, large strains analysis, stress analysis of soft materials structures and fluid-structure interaction applications.

-

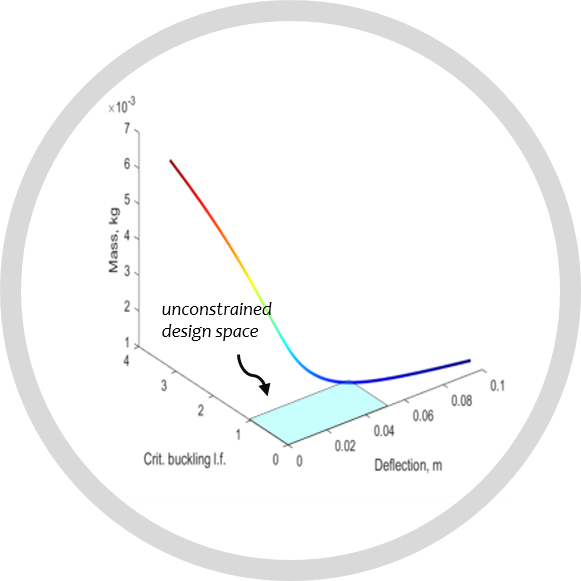

Dario Zamani obtained his Master's degree in Aerospace Engineering in October 2023, defending a thesis entitled "Defect-driven optimisation of variable angle tow laminates in AFP". In November 2023, he started his PhD at the Politecnico di Torino in the MUL2 research group on the topic "Multiphysics and mesoscale models for the analysis and design of variable stiffness composites". His current research topics are defect modelling, machine simulation and multi-objective optimisation of composite structures.